info@greeroad.cn

info@greeroad.cn

24-Hour service hotline:400-039-3669

24-Hour service hotline:400-039-3669

info@greeroad.cn

info@greeroad.cn

24-Hour service hotline:400-039-3669

24-Hour service hotline:400-039-3669

In order to ensure driving safety, the construction quality of the thermoplastic road marking must be strictly controlled. According to our many years of construction practice and continuous summary, we believe that: First of all, we must know the working principle of road thermoplastic marking; it is an important role for safe driving. At the same time, it is necessary to fully understand and be familiar with the requirements of the marking design documents; select high-quality and qualified materials; use advanced construction equipment; formulate scientific and reasonable construction organization plans; select good weather conditions for construction operations; choose experienced majors Personnel carry out construction; ensure construction safety, and conduct regular quality and safety inspections to ensure that the construction quality meets the requirements of national regulations.

1. Introduction to thermoplastic road marking line

Marking paint can be divided into cold paint type, heating type and thermoplastic type according to the construction temperature. Generally, thermoplastic types are used on highways.

Structural composition and reflection principle of thermoplastic road marking line

The main components of thermoplastic marking paint are: synthetic resin, glass beads, coloring pigments, additives, etc.

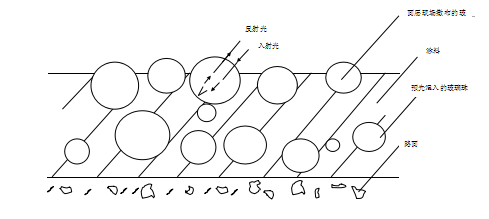

The reflective performance of the marking is formed by the glass beads in the paint reflecting the light from the car lights back to the driver's eyes. After the car lights are injected into the glass beads, each protruding glass bead on the surface of the coating is a reflective original. The light entering the glass beads is refracted inside, and reflected back to the direction of the light source on the reflective layer formed by the bottom surface of the glass beads and the paint.

The thermoplastic of synthetic resin is used to make the marking and road surface adhere firmly. Adding additives to the coating can increase the anti-sedimentation, anti-pollution and anti-discoloration of the coating film.

Features of thermoplastic road marking paint

(1) Quick-drying: thermoplastic marking paint has excellent construction and quick-drying. Regardless of the temperature, it can be dried and opened for traffic in 1-3 minutes after application.

(2) Good reflection at night: the coating and surface of the thermoplastic marking paint are filled with and spread with appropriate glass beads, and under the illumination of night lights, it has a good reflection effect and can reach a sufficient resolution distance. .

(3) Strong adhesion: There is a strong and uniform adhesion between the marking paint and the road surface, and it will not fall off quickly due to vehicle passing or vehicle starting and braking.

(4) Durability and abrasion resistance: The thermoplastic marking paint has good durability and abrasion resistance. Qualified thermoplastic road markings can be maintained for more than 20 months, complete, clear, and reflective.

Familiar with and understand the requirements of marking design documents

Before the construction of the thermoplastic road marking, in addition to being familiar with the composition, performance and working principle of the thermoplastic marking, it is also necessary to fully understand the various regulations and technical requirements of the marking design drawing to be constructed, and the construction plan and specific requirements of the construction, Draw up a detailed construction organization plan based on the climatic environment, natural geographic conditions, pavement type, pavement conditions, traffic flow, and marking line types of the construction site, and make technical clarifications with the project leader and construction workers in each process, and prepare for the construction Preparation work to ensure the smooth progress of the construction.

3. Choose qualified materials

The basic requirements for the selection of thermoplastic road marking paint are:

(1) Fast drying is required.

(2) It has good adhesion to the road surface.

(3) It has excellent weather resistance and abrasion resistance in response to various natural conditions; the color changes little during use, and the markings are kept clear, without cracking, falling off, and not easy to wear.

(4) Have and maintain good reflectivity. The reflective effect will not decrease significantly in a long period of time.

(5) It has good construction performance. That is to say, it is easy to control the thickness and width of the marking line during the construction process; the thickness of the marking line is uniform, the outline is clear, and the surface is smooth; the adhesion to the glass beads is strong.

(6) Glass beads are the main reflective material in the reflective line coating. It is mainly from the aspects of water resistance, appearance and shape, and particle size. The appearance must be transparent and spherical, and the ellipse, acute angle, and opaque should be less than the specification requirements.

(7) Other auxiliary materials such as the following paints and waterline paint must also be qualified products.

4. Use advanced construction equipment

(1) Primer machine. The primer machine is a special machine for spraying primer in the early stage of highway thermoplastic marking construction. According to the design requirements and the size of the project, suitable machines or manual roller coating can be selected.

(2) Thermoplastic Pre-heater. Choose a Thermoplastic Pre-heater with stable performance, good melting effect, simple operation and convenient maintenance. According to the size of the engineering quantity, double-cylinder or single-cylinder structure thermoplastic kettle with different tank capacity can be selected.

(3) Marking machine. Marking machine is the key equipment for road hot-melt marking construction, divided into mechanical and hand push. The key is that the markings must be drawn with straight edges, straight heads, uniform thickness, and beautiful lines; floor knives can adapt to roads under different conditions; automatic glass beads spreading device should be provided.

If you need to draw a convex oscillating marking, you need to be equipped with an oscillating marking machine. The shape, height, and spacing of the raised oscillating marking lines are required to be precise and accurate.

The general requirement is to choose a marking machine with high construction quality, fast construction speed, convenient and flexible operation, and simple maintenance.

5. Develop a scientific and reasonable construction organization plan, and make full preparations before construction

According to the requirements of the design drawings, combined with the actual situation of the construction site, a scientific, reasonable and feasible construction organization plan is drawn up in advance. In order to ensure that the various processes do not interfere with each other, the general construction sequence should generally be the main line first, then the level crossing, emergency parking zone, ramp, toll island, vibration marking, arrow, etc. For specific construction, segment construction can be used, linking segment by segment.

Materials, equipment, and personnel must be prepared before construction; in particular, safety measures and emergency handling plans must be prepared for accidents such as safety.

6. Master the natural geographical environment of the construction site and choose good weather conditions for construction

According to the chemical and physical properties of thermoplastic road marking paint are particularly suitable for use in warm areas, and the temperature during construction is above 15 degrees Celsius. However, our country has a vast territory, and the temperature difference between north and south is large; the temperature difference between winter and summer, day and night is also large in the same area. In the north or high-cold areas, thermoplastic marking lines are prone to cracks and fall off. Therefore, before the construction of the thermoplastic marking, it is necessary to understand the specific conditions such as the climate environment, geographic location, pavement type, pavement conditions, and traffic flow of the construction site. According to the actual situation, make scientific and reasonable arrangements for the materials, equipment and construction work used.

7.Use experienced operators

The construction of thermoplastic marking is a work that has a certain technical content and requires meticulous operation. Therefore, when selecting construction personnel, training and assessment must be carried out in advance. The project leader must not only be fully familiar with the composition, performance and working principle of the thermoplastic marking line, but also must fully understand the various regulations and technical requirements of the marking line design drawing, be familiar with the construction plan and the specific requirements of the construction, and be able to arrange and direct the entire The ability and experience of the hot-melt marking construction team; able to deal with all the problems in the thermoplastic marking construction; having a firm concept of safety and quality; able to rationally organize the construction according to the actual situation of the construction site.

Operators of various procedures and types of work must choose skilled workers who have been trained and are responsible for their work.

8.Take measures to ensure construction safety

Before construction, it is necessary to formulate construction safety protection measures and emergency response plans for sudden safety accidents according to the actual conditions of the site, and establish safety guidelines. Develop a construction safety system and implement a safety responsibility system; allocate full-time safety personnel to conduct safety training and safety education for all employees; provide necessary safety facilities and safety equipment; all construction personnel must wear uniform clothing with eye-catching colors; conduct safety inspections at any time , And deal with the problem promptly.

Especially when constructing on roads that are already open to traffic, the construction method that closes half of the road must be used for construction. Set up corresponding warning and deceleration signs in front of the construction section according to regulations; use isolation cones and other facilities to close the construction section. And arrange full-time security personnel to direct and guide passing vehicles, and it is strictly forbidden to drive into the enclosed construction area. All construction vehicles and equipment used at the same time must be equipped with warning lights and construction signs; all construction personnel must wear obvious reflective work clothing to ensure the safety of construction personnel and vehicle equipment.

9. Strictly construct in accordance with specifications, attach importance to every aspect of construction, and adhere to quality. During the construction of hot melt marking, the construction is carried out according to the following procedures:

(1) Construction preparation: debug equipment in advance, prepare materials and various tools; take safety measures.

(2) Heating and melting of paint: This link is very important. It is necessary to master the firepower, feeding speed, and strengthen the stirring. After the temperature reaches the required (180°C), it can be poured into the marking car for use.

(3) Cleaning the road surface: Cleaning the road surface is the primary condition to ensure the adhesion effect, and it is the foundation of the hot-melt marking construction. First, we must clean up the dust, mud and other debris on the road. If it is wet or there is water, wait until it is dried or heated with a gas flame before construction.

(4) Stakeout. Generally, the completed curbs and odometer are recorded as reference objects, and the large samples are released according to the design drawings, and the water line is painted with water line paint.

(5) Apply paint. Some are also called primers, and apply a layer of primer evenly along the laid waterline. Depending on the road surface, it can be applied once or twice.

(6) Painting construction. Painting construction is a key link in the construction of hot melt marking. The marking equipment must be up to the state, and the paint thickness must be adjusted to the design thickness (usually 1.5-1.8 mm); at the same time, check the width, paint color, the amount and uniformity of the glass bead distribution; whether the marking edges and ends are neat No burrs; the glass beads are scattered in a state where half is embedded in the paint and half is exposed, and its reflective effect is good.

(7) Check and repair open traffic. After the construction is completed, a serious inspection and repair is required. After the quality is fully qualified, the site can be cleaned up and the traffic can be opened.

Concluding remarks:

Thermoplastic road marking is an important part of highway traffic safety, and it plays a very important and irreplaceable role in highway use. Therefore, during construction, construction must be carried out in strict accordance with national regulations. Strictly check all the processes and links of materials, equipment, personnel and construction, strictly control the construction quality, ensure that the requirements of the regulations are met, and provide effective guarantees for road safety.

Hot news

Breaking news

Contact us

Great Road (China) ,All rights reserved.